Innovative Fabrics, Unsurpassed Design

Expertise in both fabric technologies and garment design makes Kimberly-Clark the leader in comfortable, protective apparel.

Fabric

Technologies

Reflex® Coverall Design vs. ANSI Sizing

Seam Details

Taped Seam Data

Kleenguard® Select, Extra Apparel

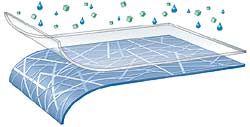

Microforce* Barrier SMS Fabric

Outer layers — Cloth-like, yet tough and abrasion-resistant spunbond polypropylene

Middle layer — Intricate web of microfibers filter out many water-based liquids and dry particulates

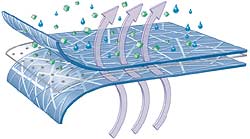

REPEL®

Apparel Fabrics

Outer layers — Film coating resists splash and spray from many liquids and dry particulates

Middle layer — Cloth-like, yet tough and abrasion-resistant spunbond polypropylene

Kleenguard® Ultra Apparel Fabric

Outer layers — Cloth-like, yet tough and abrasion-resistant spunbond polypropylene

Middle

layer — Breathable microporous film offering splash and spray

resistance to many liquid chemicals and dry particulates

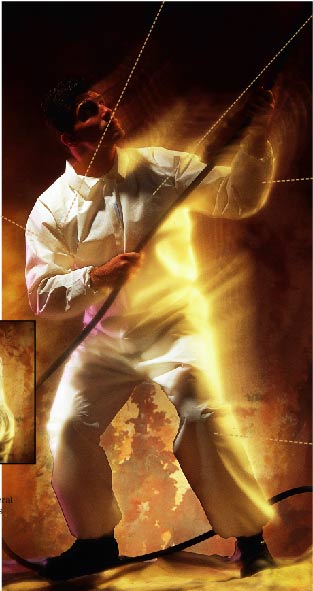

Our REFLEX® Coverall Design Means Extra Comfort And Longer Wear

Kimberly-Clark®

Protective Apparel features our unique, patented REFLEX® Coverall

Design which exceeds ANSI minimum standards. Kimberly-Clark garments

with the Reflex® Coverall Design are larger and 7.5 times less likely

to rip out vs.coveralls sewn to ANSI minimum sizing. That means they

provide longer wear, which results in a lower cost-in-use and increased

worker productivity.

A serged seam is a basic stitched seam. Triple thread overlap stitching provides strength and durability.

Our Quality Shows In Every Seam

The seams on a garment are as important as the fabric itself. Kimberly-Clark offers three different seams to choose from — serged, bound, and taped.

A taped seam is serged, then reinforced with a Saranex® 23P film tape that’s resistant to water and many liquid chemicals.

If your application requires a taped seam that is chemical resistant, you should ensure that the tape offers appropriate resistance to the chemical involved.

| ASTM

F1001 Liquid Chemicals |

PENETRATION ASTM F903 |

| Acetone | Pass |

| Acetonitrile | Pass ! |

| Carbon Disulfide | Pass ! |

| Dichloromethane | Pass ! |

| Diethylamine | Pass ! |

| n,n-Dimethylformamide | Pass ! |

| Ethyl Acetate | Pass |

| n-Hexane | Pass |

| Methanol | Pass ! |

| Nitrobenzene | Pass ! |

| Sodium Hydroxide (50%) | Pass |

| Sulfuric Acid (98%) | Pass |

| Tetrachloroethylene | Pass ! |

| Tetrahydrofuran | Pass |

| Toluene | Pass ! |

| ! WARNING: Fabric passes penetration testing; however, the chemical is a known or suspected carcinogen or skin absorbed toxin. | |

Questions or comments about this site? Contact the Webmaster.

All names,

logos and trademarks are the property of Kimberly-Clark Corporation or its

affiliates.

®

Registered Trademark or *Trademark of Kimberly-Clark Corporation.

© 2001 Kimberly-Clark Corp. All Rights Reserved. Your visit to this site

and use of the information hereon is subject to the terms of our Legal

Statement. Please review our Privacy Policy.