Made from Saranex® 23P film laminated to a durable, lightweight nonwoven interior that has a comfortable, cloth-like feel against the skin. Designed with no seams in the front of the garment (the primary splash zone). Available with bound seams or seams taped with Saranex® film.

TYPICAL

USES

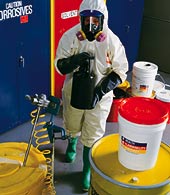

Chemical Handling

Chemical Mixing

Chemical Clean-Up

Hazardous Material

Hazardous Waste

Industrial Hazmat

Petrochemical

Utilities

PHYSICAL

PROPERTIES

GARMENT STYLES

ACCESSORIES

SIZING & PRODUCT CODES

HAZARD-GARD*

Apparel Fabrics

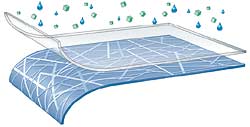

Outer layers — Film coating resists splash and spray from many liquids and dry particulates

Middle layer — Cloth-like, yet tough and abrasion-resistant spunbond polypropylene

| ASTM

F1001 Liquid Chemicals |

PENETRATION ASTM F903 |

| Acetone | Pass |

| Acetonitrile | Pass ! |

| Carbon Disulfide | Pass ! |

| Dichloromethane | Pass ! |

| Diethylamine | Pass ! |

| n,n-Dimethylformamide | Pass ! |

| Ethyl Acetate | Pass |

| n-Hexane | Pass |

| Methanol | Pass ! |

| Nitrobenzene | Pass ! |

| Sodium Hydroxide (50%) | Pass |

| Sulfuric Acid (98%) | Pass |

| Tetrachloroethylene | Pass ! |

| Tetrahydrofuran | Pass |

| Toluene | Pass ! |

| ! WARNING: Fabric passes penetration testing; however, the chemical is a known or suspected carcinogen or skin absorbed toxin. | |

| Physical Properties |

Test

method

|

Results

|

| Tensile Strength (MD) |

ASTM

D5034

|

52.8lbs

|

| (CD) |

40

lbs

|

|

| Trapezoidal Tear (MD) |

INDA

IST 100.2

|

19.6

lbs

|

| (CD) |

9.5

lbs

|

|

| Mullen Burst |

ISO

13938-1

|

54.3

psi

|

| Flammability |

CPSC

1610

|

Class

1

|

| Barrier Properties |

Test

method

|

Results

|

| Hydrohead |

AATCC

127-1998

|

625

cm

|

| Blood Penetration |

ASTM

F1670

|

Pass

|

| Blood-Borne Pathogens |

ASTM

F1671‡

|

Pass

|

|

‡ Standard Test Method for Resistance of Materials Used in Protective Clothing to Penetration by Blood-Borne Pathogens Using Phi-X174 Bacteriophage Penetration as a Test System.

|

||

| When selecting chemical protective clothing, it’s important to be sure that the garment offers adequate resistance to the chemicals being handled in your workplace. | |||

| ASTM

F1001 Liquid Chemicals |

PENETRATION ASTM F903 |

Permeation

ASTM F739 Normalized Breakthrough (min.) |

Rate µg/cm2min |

| Acetone | Pass | 22 | High |

| Acetonitrile | Pass ! | 35 | 0.8 |

| Carbon Disulfide | Pass | Immediate | High |

| Dichloromethane | Pass ! | Immediate | High |

| Diethylamine | Pass | 20 | High |

| n,n-Dimethylformamide | Pass ! | 109 | 0.45 |

| Ethyl Acetate | Pass | 18 | 0.8 |

| n-Hexane | Pass | >480 | <0.008 |

| Methanol | Pass | >480 | 0.01 |

| Nitrobenzene | Pass ! | 77 | 3.8 |

| Sodium Hydroxide (50%) | Pass | >480 | <0.08 |

| Sulfuric Acid (98%) | Pass | >480 | <0.022 |

| Tetrachloroethylene | Pass | 50 | 8.2 |

| Tetrahydrofuran | Pass | Immediate | High |

| Toluene | Pass | 6 | High |

|

Additional testing information and detail is available upon request. ! WARNING: Fabric passes penetration testing; however, the chemical is a known or suspected carcinogen or skin absorbed toxin. |

|||

| GARMENT SIZING AND FABRIC SELECTION CHART [click here for complete product line] | |||||

|

The last digit in the product code number (x) indicates size, as follows: 2

= medium |

Zipper Front, storm flap |

|

|

|

|

|

GARMENT

BRANDS

|

|||||

|

HAZARD-GARD*

II

[bound] - white |

4562x | 4563x | 4565x | ||

|

HAZARD-GARD*

II

[taped] - white |

4564x

|

4566x

|

4569x

|

4567x

|

|

|

®Mylar

is a Registered Trademark

of the DuPont de Nemours and Co.

|

|||||

| COVERALLS BOUND SEAMS - White |

||

| Zipper

front, storm flap |

||

| STYLE | SIZE | CASE COUNT |

| 45623 | L | 12 |

| 45624 | XL | 12 |

| 45625 | XXL | 12 |

| 45626 | XXXL | 10 |

| 45627 | XXXXL | 10 |

| LEVEL B/C Suit | ||

| Zipper front, storm flap, elastic wrists, ankles, hood | ||

| 45633 | L | 12 |

| 45634 | XL | 12 |

| 45635 | XXL | 12 |

| 45636 | XXXL | 10 |

| 45637 | XXXXL | 10 |

| LEVEL B/C Suit | ||

| Zipper front, storm flap, elastic wrists, hood & boots | ||

| 45653 | L | 12 |

| 45654 | XL | 12 |

| 45655 | XXL | 12 |

| 45656 | XXXL | 10 |

| 45657 | XXXXL | 10 |

| COVERALLS

[Saranex® 23P] TAPED SEAMS - White |

||

| LEVEL B/C Suit | ||

| Zipper front, storm flap, elastic wrists, ankles, hood | ||

| STYLE | SIZE | CASE COUNT |

| 45643 | L | 12 |

| 45644 | XL | 12 |

| 45645 | XXL | 12 |

| 45646 | XXXL | 10 |

| 45647 | XXXXL | 10 |

| LEVEL B/C Suit | ||

| Zipper front, storm flap, elastic wrists, hood & boots | ||

| 45663 | L | 12 |

| 45664 | XL | 12 |

| 45665 | XXL | 12 |

| 45666 | XXXL | 10 |

| 45667 | XXXXL | 10 |

| LEVEL B/C Respirator Suit | ||

| Respirator Suit, back zipper with storm flap, hood with Mylar® faceshield, booties with boot flaps, elastic wrists with wrist flaps, air inlet | ||

| 45693 | L | 3 |

| 45694 | XL | 3 |

| 45695 | XXL | 3 |

| 45696 | XXXL | 3 |

| 45697 | XXXXL | 3 |

| LEVEL B/C Encapsulated Suit | ||

| Encapsulated Suit, expanded back, back zipper with storm flap, hood with Mylar® faceshield, booties with boot flaps, elastic wrists with wrist flaps | ||

| 45673 | L | 3 |

| 45674 | XL | 3 |

| 45675 | XXL | 3 |

| 45676 | XXXL | 3 |

| 45677 | XXXXL | 3 |

Questions or comments about this site? Contact the Webmaster.

All names,

logos and trademarks are the property of Kimberly-Clark Corporation or its

affiliates.

®

Registered Trademark or *Trademark of Kimberly-Clark Corporation.

© 2001 Kimberly-Clark Corp. All Rights Reserved. Your visit to this site

and use of the information hereon is subject to the terms of our Legal

Statement. Please review our Privacy Policy.